![]()

Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : zhimachine@foxmail.com

Tel : +86 18221614363

processing capacity:customizable

Application scope:application range: suitable for drying river sand, river sand, sea sand, yellow sand, emery sand, garnet sand, quartz sand, foundry sand, slag, etc.

Product introduction: Sand drying machine application range: suitable

for drying river sand, river sand, sea sand, yellow sand, emery sand,

garnet sand, quartz sand, foundry sand, slag, etc.

Sand dryer

Production capacity (t/d): customizable

Area (㎡): Customizable

Sand dryer application range: suitable for drying river sand, river sand, sea sand, yellow sand, emery sand, garnet sand, quartz sand, foundry sand, slag, etc.

Heat source configuration: suitable for multiple fuels

Environmental protection configuration: supporting use of multi-stage dust removal equipment

Product Introduction

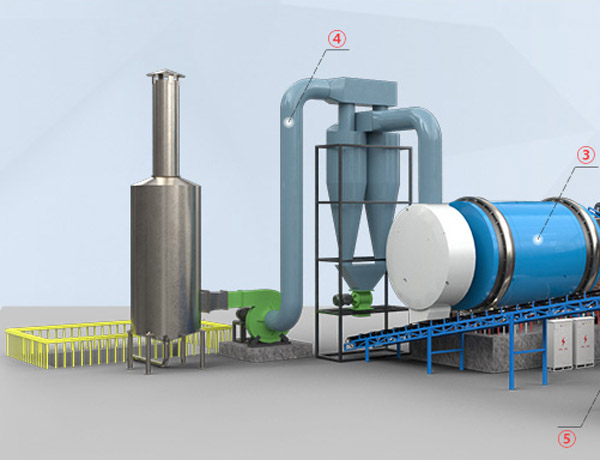

Sand dryer, also known as sand three-layer tumble dryer, sand three-pass tumble dryer, is developed on the basis of a single-tube dryer, and it is an industrial drying material with good fluidity. According to the requirements of different industries for the final moisture content of the dried material, the moisture content of the dried material can reach 0.5-1% or less. At present, the company's three-cylinder dryer has mature technology and has been inspected for river sand, river sand, sea sand, yellow sand, emery sand, garnet sand, quartz sand, foundry sand, slag and other materials.

The sand dryer (sand drying equipment, sand drying production line) is used to dry sand and river sand. It is also a drum-type drying equipment. In fact, it is safe and reliable to operate, and it is convenient and quick to operate. Loved by the majority of users, and it has strong adaptability, can work continuously, and has a large processing capacity.

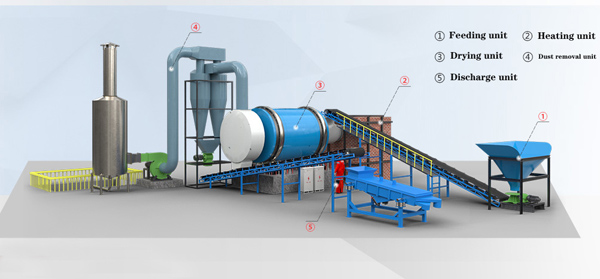

The main components of the equipment are: cylinder, front roller ring, rear roller ring, gear, stop roller, drag roller, pinion, discharge part, lifting plate, reducer, motor, hot air duct, feed chute, furnace In addition, according to the needs of different users, gas generators, combustion chambers or supporting elevators, belt conveyors, metering feeders, cyclones, induced draft fans, etc. can be designed specifically for customers.

It can be mainly used for drying river sand, dry-mixed mortar, yellow sand, cement plant slag, clay, coal gangue, mixture, fly ash, gypsum, iron powder, limestone and other raw materials. It is widely used in building materials, chemical industry, casting And other industries. The main ones are used for drying materials such as fly ash, slag, sand, coal, iron powder, ore, blue carbon and so on.

working principle

The production line of the river sand dryer is composed of heat source system, feeding system, conveyor belt, feeding chute, drying equipment, discharge belt, vibrating grading screen, dust removal system, induced draft fan, electric control system and other equipment. The sand is sent to the hopper by a belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The inclination of the feeding pipe should be greater than the natural inclination of the material so that the material can flow into the sand dryer (yellow sand dryer) smoothly. The dryer cylinder is a rotating cylinder slightly inclined to the horizontal. The material is added from the higher end, the heating medium enters from the lower end, and it comes into countercurrent contact with the material, and there is also the heating medium and the material flow into the cylinder together. With the rotation of the cylinder, the material moves to the lower end by gravity. When the wet material moves forward in the cylinder, it directly or indirectly receives heat from the heating medium, so that the wet material can be dried and sent out from the discharge end through a belt or screw conveyor. A lifting plate is installed on the inner wall of the cylinder of the sand dryer (yellow sand dryer). Its function is to pick up and scatter the materials to increase the contact surface between the materials and the air flow to increase the drying rate and promote the materials go ahead. The heating medium is generally divided into hot air, flue gas, etc. After the heating medium passes through the dryer, a cyclone dust collector is generally required to capture the materials carried in the gas. If it is necessary to further reduce the dust content of the exhaust gas, it should be discharged after passing through a bag filter or a wet dust collector.

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapManufacturer